In the past, glass imaging was mainly realized by painting, etching and screen printing, which was costly and complicated.

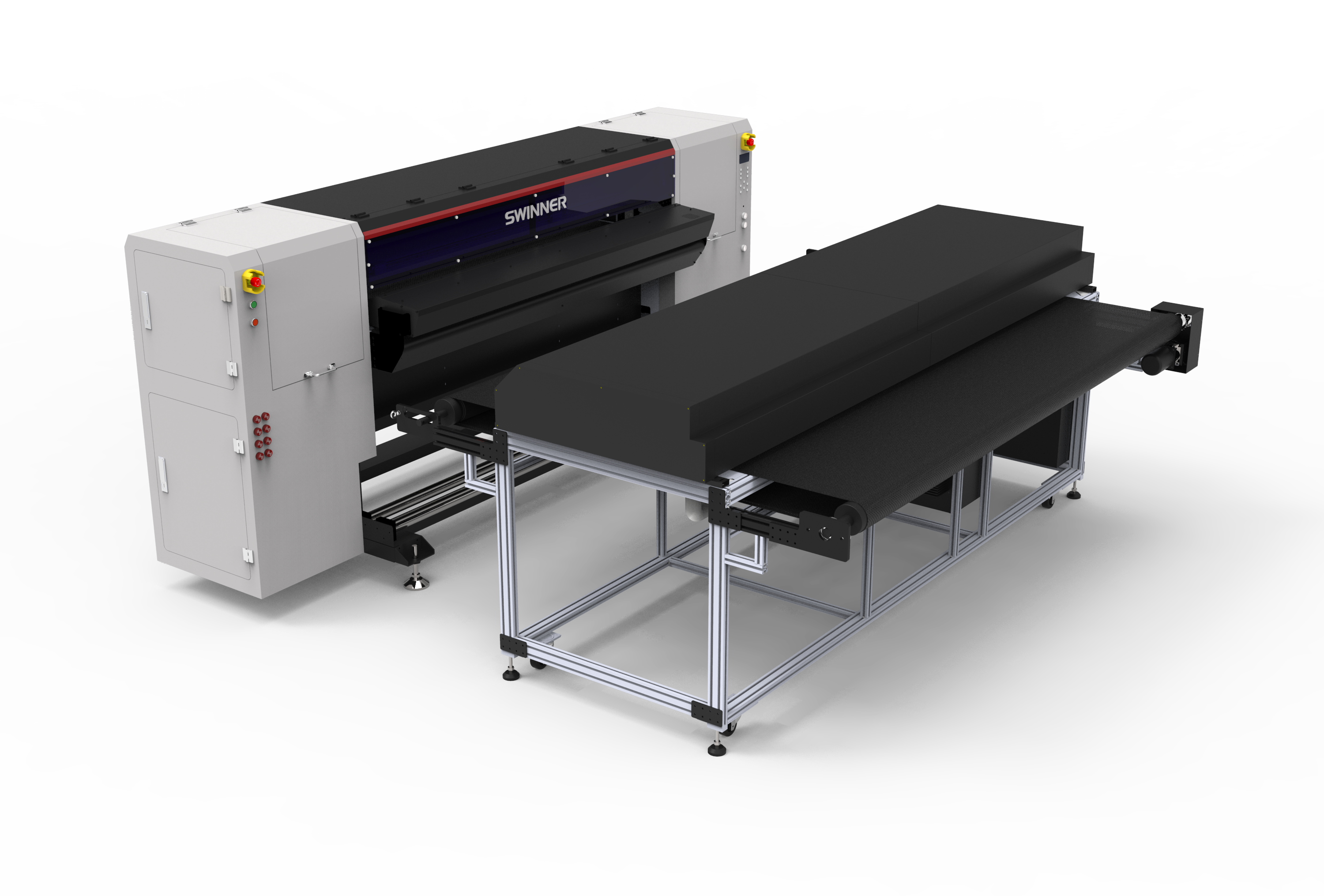

With the development of science and technology, UV inkjet printer technology has rapidly occupied the glass printing market. Using UV inkjet printing technology, we can obtain higher-end and higher quality image without post printing process. We can generate personalized products in a short time with low cost. It is a popular choice in the current glass market..

UV Printing Adhesion Improvement Tips

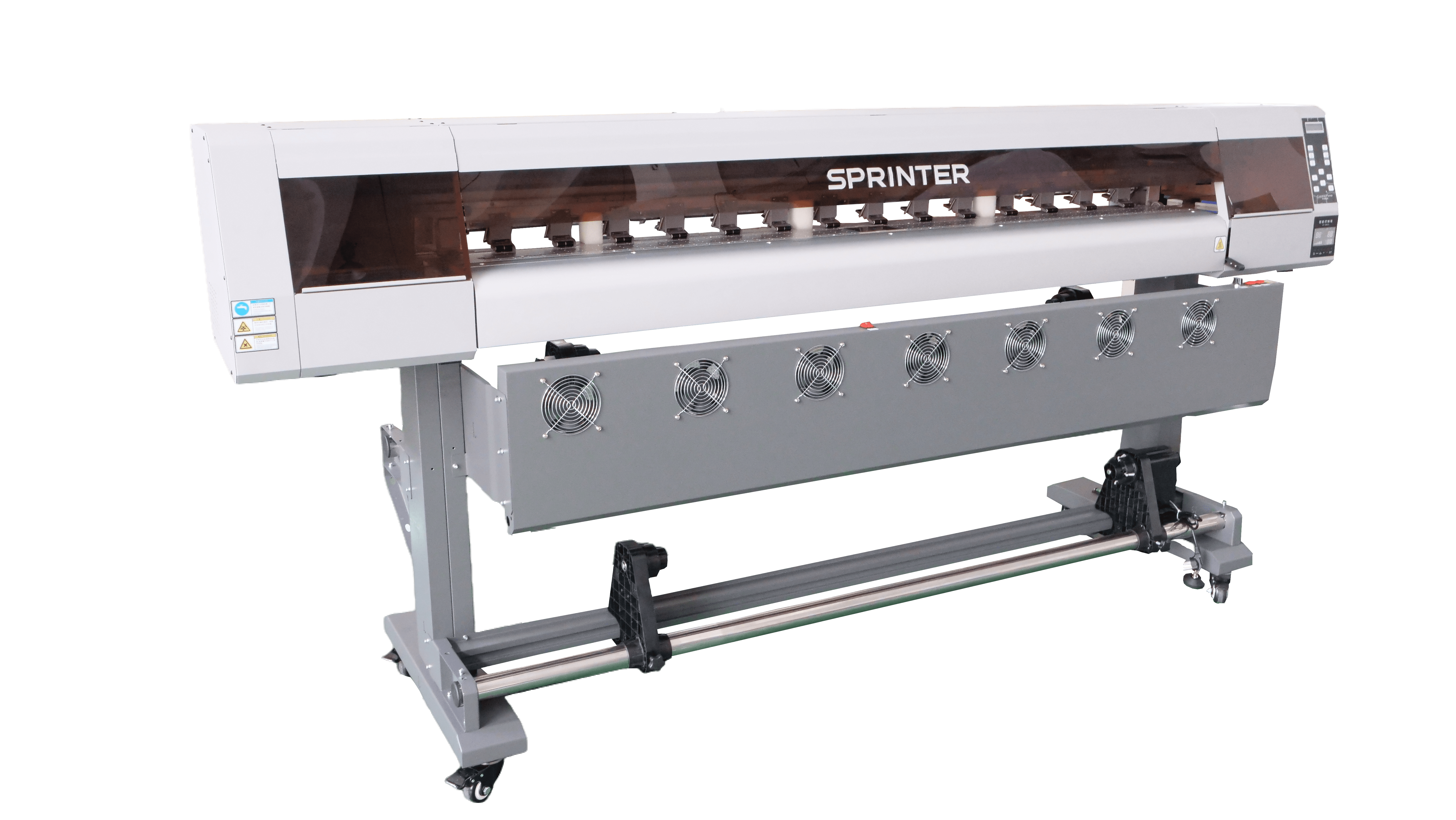

The success of printing on glass using UV inkjet printers depends on adhesion. How to improve the adhesion of ink on glass when using UV-LED printing, SPRINTER shares three tips.

一.Prime Coat

The primer is evenly coated on the glass surface with a proper amount of non-woven fabric to improve the adhesion of UV ink, so that the pattern is not easy to fade and fall off.

二.Print the Primer Coating on the UV Machine with a Special Printhead.

This method prints the primer exactly where it is needed, reducing labor and saving the amount of primer.

三.Plasma Treatment

It mainly reacts with the photosensitive curing agent and photopolymerization initiator in the UV coating or paint. Through cross-linking polymerization between complex particles, the UV coating or UV paint can be quickly cured into a film in a very short time to achieve the expected purpose of surface treatment.

Glass Door of Shanghai SPRINTER Showroom

How to improve print quality

- Selection of UV Ink

The choice of UV ink is also different according to the difference of the printhead. The principle, internal structure, piezoelectric crystal, orifice size and ignition frequency of various types of inkjet printheads on the market are different. It is particularly important to select UV ink that conforms to the characteristics of the printhead.

Use the UV ink specified by the manufacturer is your best choice. The UV ink is recommended to customers after strict screening and multiple tests. The recommended ink performance is more consistent with the characteristics of its own machine, and the manufacturer or the manufacturer's designated agent will also provide corresponding after-sales services.

The imported ink of SPRINTER has been tested for many times in terms of compatibility, color density, scratch resistance and adhesion, so that the machine can display the advantages of ink to the greatest extent. Printed on the glass, the color is bright, and the color expression and saturation are sufficient. We have a variety of types of inks for you to choose from, such as hard, neutral and soft inks.

- Improve Printing Adhesion

At present, UV printing glass needs to be processed. The treatment methods are divided into pre-treatment and post-treatment.

The pre-treatment has been described in detail in the UV printing adhesion improvement tips; post-processing requires special processing after printing.

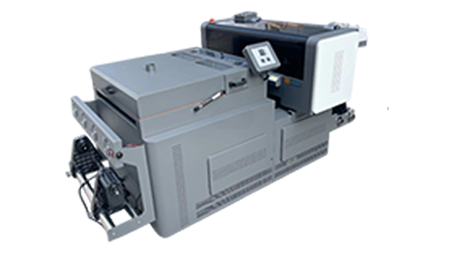

- Equipment Selection

In the selection of UV printing glass materials, it is generally recommended that you use thicker glass, such as tempered glass, whose printing effect will be better than that on ordinary glass. This kind of glass material has higher requirements on the platform of the machine.

SPRINTER UV printer adopts a hard oxidation chamber adsorption platform (plane accuracy is within 0.20mm), with a maximum load capacity of 50kg / ㎡. The super adsorption force and load capacity ensure the continuity of the printing process.

Print mode and applicable model

Generally speaking, the printing mode of glass is divided into "color+white", "white+color", "color+white+color", "color+white+varnish", etc.