Long holidays are coming, in the happy at the same time also need to do the appropriate maintenance measures for the machine. The following to share with you the machine maintenance methods.

Maintenance method when the machine is not working during 3-7 days holiday.

- Print the printhead status to determine whether the printhead is in good or bad condition, and mark it.

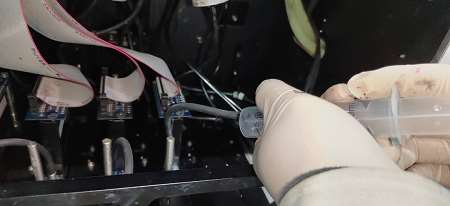

- Turn off the machine and use clamps or hemostats to hold the inkjet inlet tube. As shown in the figure below

-

open the front of the printhead exhaust pipe, with a clean syringe to extract cleaning fluid, from here to fill, and slowly and evenly flush the printhead, the printhead internal ink all empty.

-

after the printhead flushing (that is, no obvious color changes in the cleaning fluid flushed out, flushing requires a slow and even rinse, do not vigorously flush), and then inject air into the internal printhead, so that there is no residual cleaning fluid inside the printhead, so that the internal drying.

-

Put a board on top of the platform, lay the non-woven fabric flat on the board, then move the printhead position of the cart to the top of the non-woven fabric and manually turn the hand wheel to let the printhead and the non-woven fabric fit. Use the light-blocking dust cover to cover the cart and do shading treatment.

Maintenance methods for holidays over 7 days.

- Print the printhead status to determine whether the printhead is in good or bad condition, and mark it.

- Clean the entire ink path of ink. Pull out the inlet tube from the ink barrel containing the ink and click on the ink press in the open software state to press the ink out of the printhead exhaust tube until bubbles appear in the printhead (note: the ink can be recycled, use a new disposable cup for each color)

-

Cleaning the ink circuit. Function: To prevent the ink from settling inside the pipeline.

- When the ink supply of cleaning solution is completed, click on the pressed ink and repeat the operation until the cleaning solution pressed from the printheadshows a clear color or light color.

- Remove the disposable water cup and keep supplying ink until bubbles appear in the printhead.

-

Turn off the machine and use clamps or hemostats to hold the ink feed tube of the printhead. Open the exhaust pipe at the front of the printhead, use a clean syringe to extract the cleaning fluid and fill it from here, and slowly and evenly rinse the printhead until the cleaning fluid coming out of the printhead printhead hole shows a clear color or light color; then use a syringe to hit the air to empty all the cleaning fluid inside the printhead, so that no residual cleaning fluid exists inside the printhead to do internal drying.

-

A board is placed on top of the platform, the board is laid flat on the non-woven fabric, and then the carriage printhead position moved to the non-woven fabric above, manually rotate the hand wheel so that the printhead and non-woven fabric fit. Use the light-blocking dust cover to cover the cart and do shading treatment.

If you have any questions, please feel free to contact our technical staff

SPRINTER after-sales service team

will be happy to serve you!