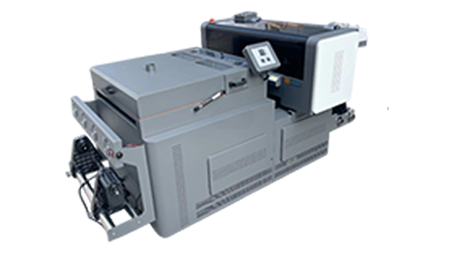

EPS1602/EPS1802

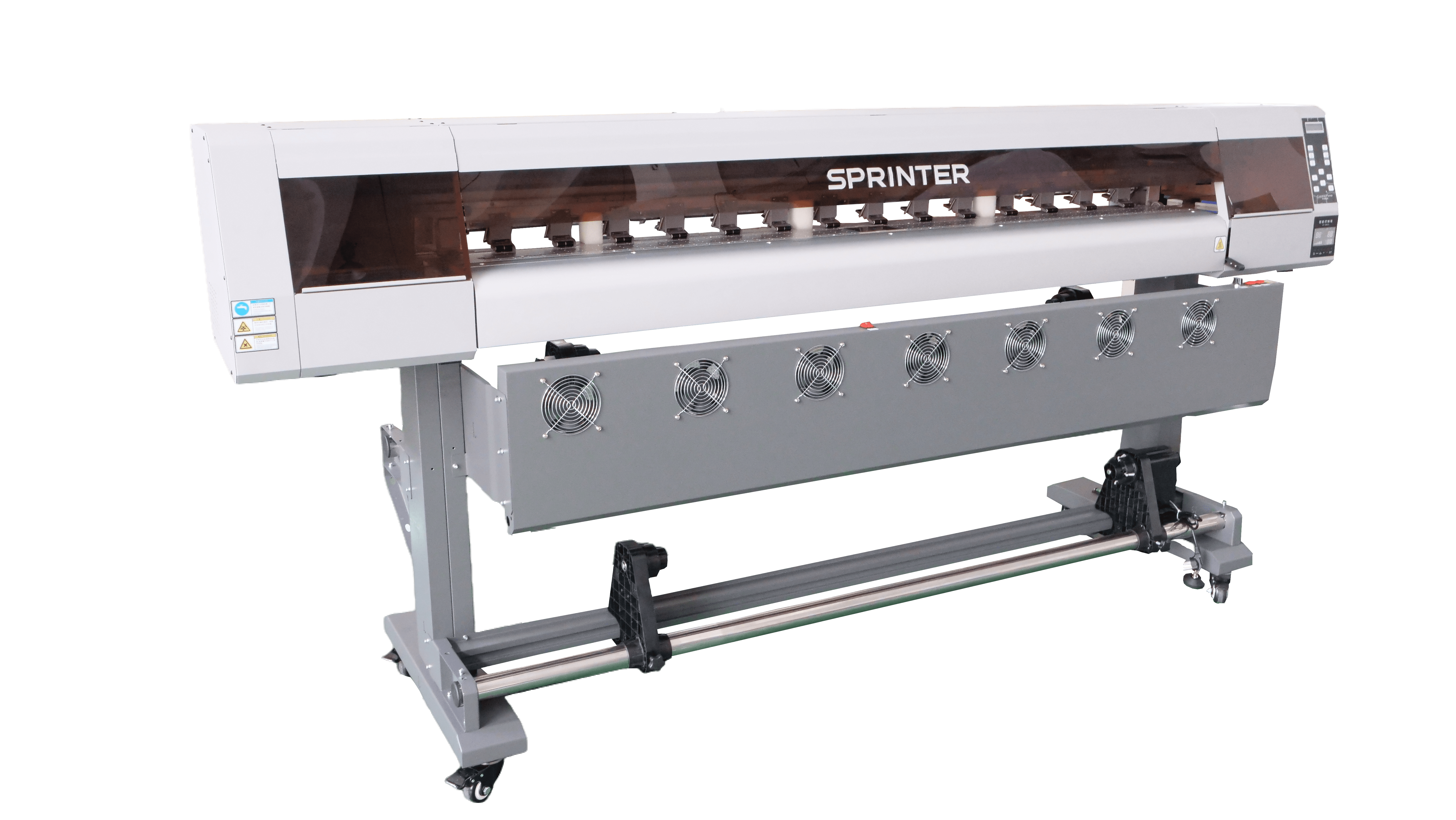

If you’re looking for an eco-friendly large format printer that offers stunning prints with low environmental impact, then an eco-solvent printer may be the perfect option for you.

Key benefits

- The ink has virtually no odour as they don’t contain as many VOC

- Safe for operators and the environment

- Increase durability, and improve print quality

- Is ideal for a variety of different substrates

- For large-scale projects or high-volume printing

- More cost-effective in the long run

Advantages

- Eco solvent printer produces very little waste. The solvents used in eco-solvent printing evaporate completely, so there is no need for hazardous waste disposal.

- Eco-solvent prints are more durable and resistant to fading, making them ideal for outdoor applications.

- Eco solvent printer often require less energy to operate, further reducing their environmental footprint.

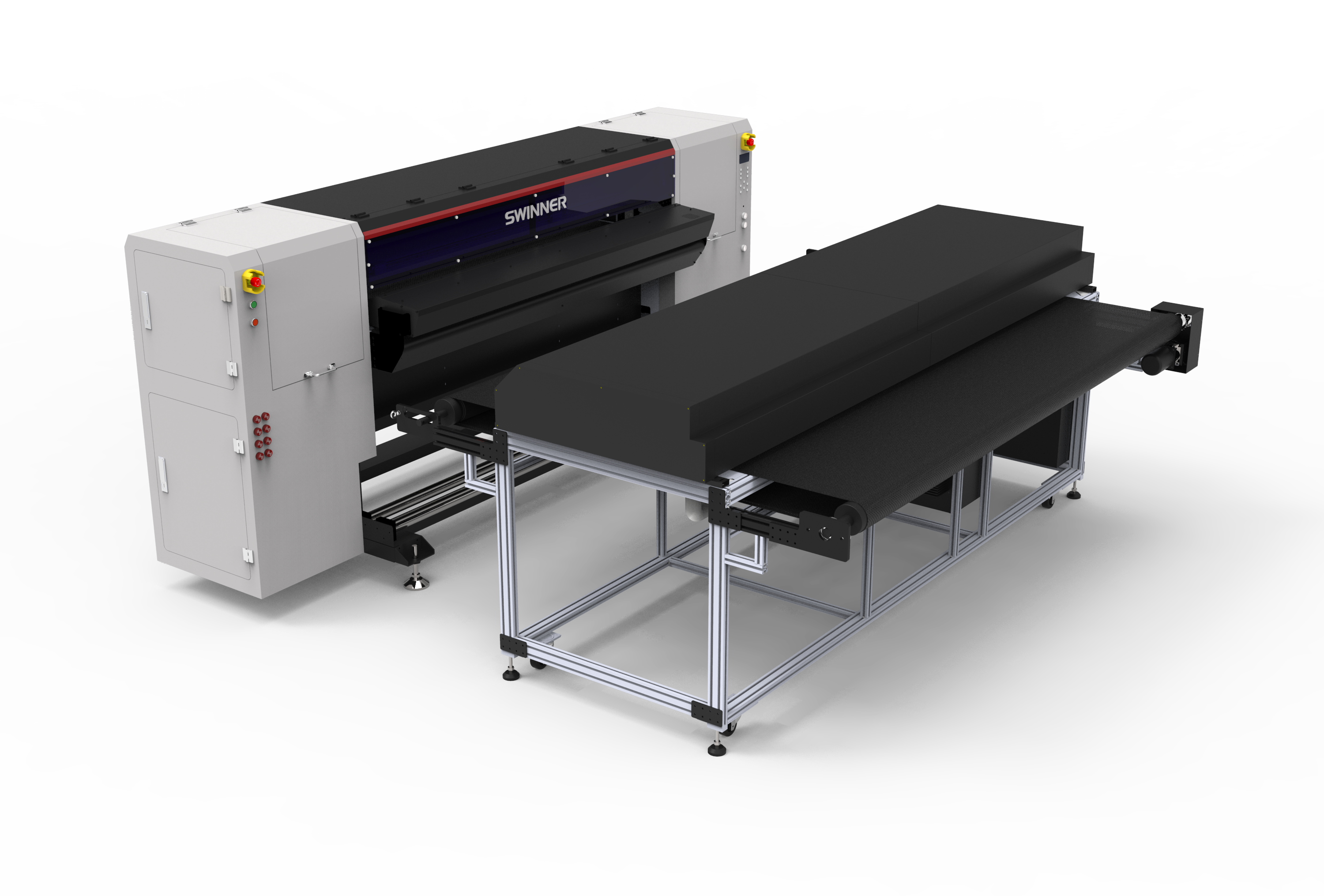

Machine systems

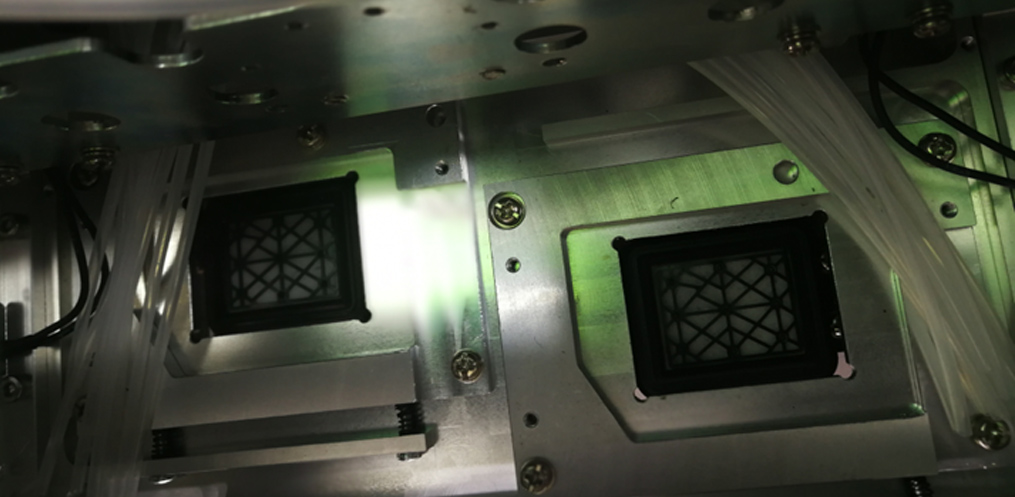

- Printhead maintenance system

- Feed up and take up system

- Infrare Heating

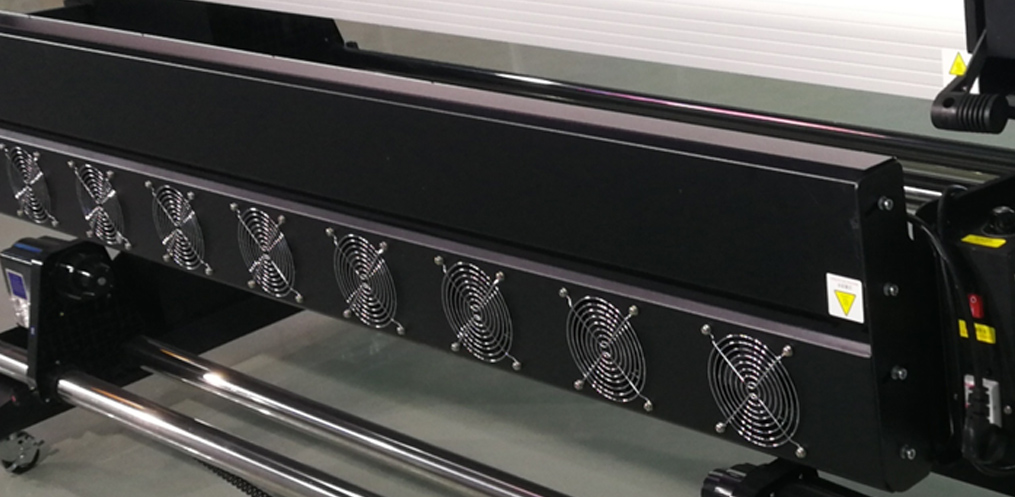

- Fan drying

- Ink tank lack detection system

EQUIPMENT

Rich printing solutions, Makes you RICH

EPS1602 dimension diagram

EPS1802 dimension diagram

Features

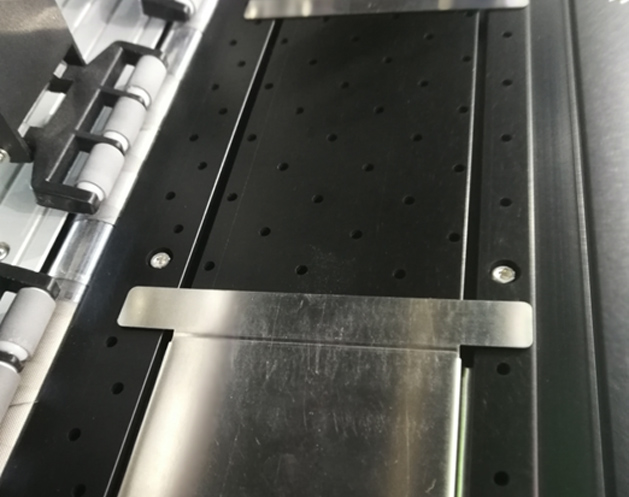

Print Platform

It can better absorb the materials on the platform, ensure the flatness of the materials, improve the smoothness of paper feeding, and ensure the stability of printing.

Printhead Maintenance System

Equipped with advanced intelligent automatic printhead cleaning and moisturizing device, the ink is good and keeps the ink flowing smoothly.

Infra-red heating

Intelligent high-power touch screen infrared heating to ensure a good drying of the picture when printing at high speed.

Press Paper Wheel

The contact area between the three wheels and the material is larger, the friction is greater, and the fixation is more accurate. The pressure of the three gears can be adjusted to adapt to the material with different thickness.

Ink Supply System

Intelligent adjustment of liquid level height of high specification continuous ink supply system effectively ensures ink smoothness and improves printing efficiency.

Media Heater Control

Constant temperature printing is realized by heating the carriage base.

Applications

Technical Specs

| Model | EPS1601,EPS1801 | |

| Print Sizes | Max. Print size | 1600mm/1800mm |

| Enviromental Conditions | Temperature 15-40℃,Humidity 40%-65℃ | |

| Bearable weight | Max. 75kg | |

| Color channels | Max. 4; CMYK | |

| Printhead | Max. No.s | 1 |

| Type | Epson i1600/i3200/XP600 | |

| Software | Control | Hanson control system |

| RIP | Maintop,RUIIN,Photoprint option | |

| Computer (Not included) | Windows 7/10; 64bits | |

| Data transfer | USB 3.0 | |

| Resolution | 540dpi; 720dpi; 1440dpi | |

| Machine size & N.Weight | EPS1602: 2585*670*1300mm, 177kg EPS1802: 2785*670*1300mm, 200kg |

|

| Packing | Wooden case | |

| Package Size & G.Weight |

EPS1602: 2700*570*650mm, 240kg EPS1802: 2900*670*650mm, 270kg |

|

*Specifications subject may change without notice. Please confirm with sales representative for more details