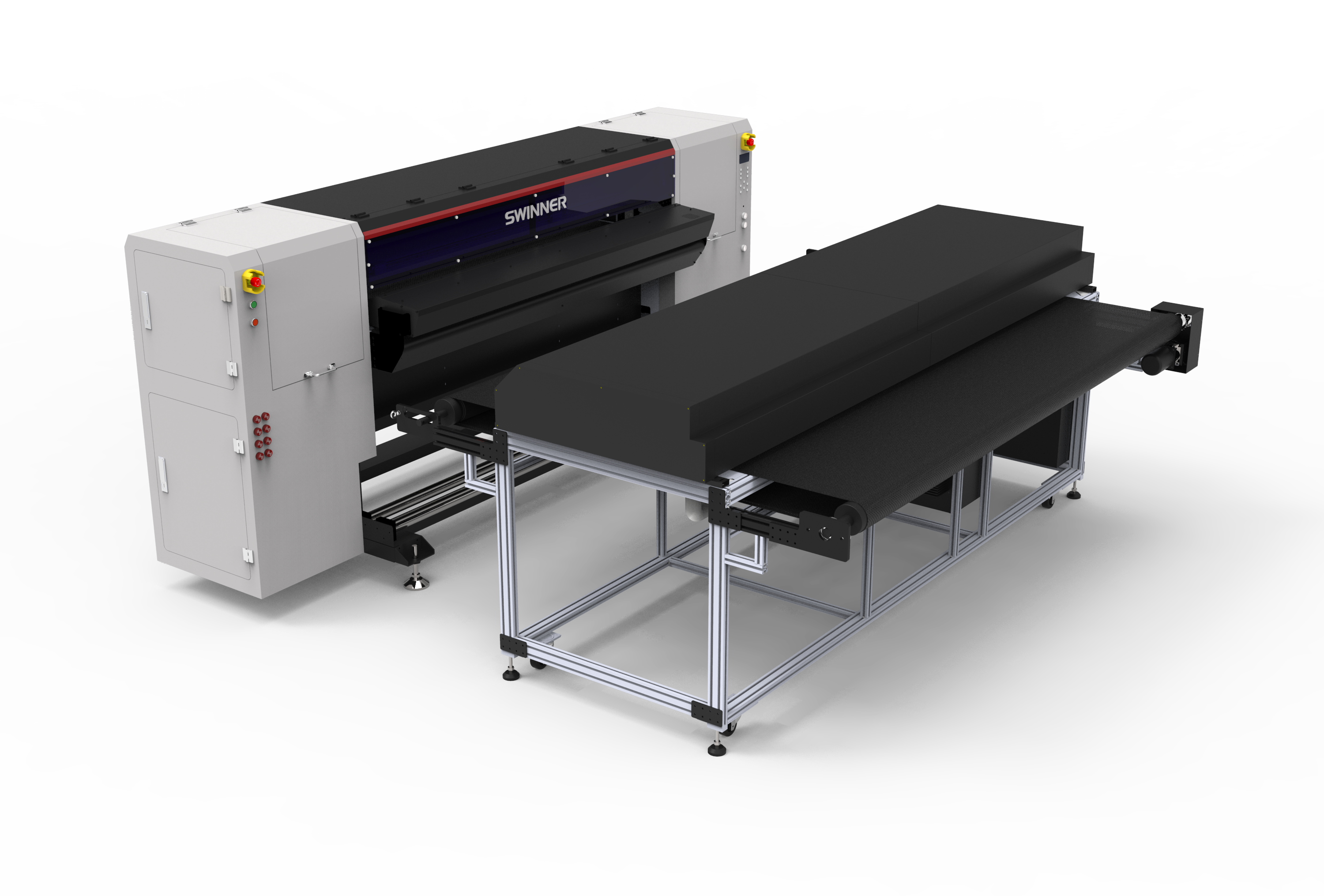

The SPRINTER Power Pro 3200 is a professional-grade industrial roll-to-roll printer designed to meet the diverse needs of the printing industry. Whether for small to medium-sized businesses or large advertising companies, this robust and advanced machine is built to handle a variety of applications with ease. The Power Pro 3200 aims to support your production process, ensuring excellent quality and high-efficiency output for every printing task.

Features & Specifications:

- Printing Speed: Up to 100 sqm/h

- Max Resolution: 635x2160 dpi

- Ink Drop Size: 6–18 pl

- Color Configuration: CMYKWV or CMYKLcLm

- Max Printing Size: 3.2×50 meters

- Max Material Size: 3.22×50 meters

- Max Media Thickness: 25mm (Max 30 kg/sqm)

- Power Supply: 220V (Dual Inputs)

- Max Power Consumption: 10.8 kW

- Weight: 2200 kg

- Machine Dimensions: 597016601640mm / 5970 x 3360 x 1640 mm (with optional front/rear platforms)

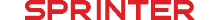

The Power Pro 3200 - 3.2m UV Belt Conveyor Printer combines the advantages of both roll-to-roll and flatbed printing. For flexible, stretchable materials like soft film, the system allows materials to be fully spread and tensioned on the platform, ensuring smooth and wrinkle-free movement through the conveyor system and feeding rollers, eliminating the need for leader cloths and reducing material costs. With the optional front and rear platforms, it also functions as a flatbed printer, saving space compared to traditional flatbed machines. The belt-driven feed system allows for unlimited board length printing.

The Power Pro 3200 can handle a wide range of materials, including advertising, POS materials, packaging, retail space design products, as well as decorative items for residential, office, and exhibition spaces—such as wall and ceiling panels, glass, tiles, natural and artificial stone. It's also widely used in furniture and glass production for printing decorative finishes on cabinet doors, panels, colored glass windows, and more. Additionally, it can print on doors, blinds, shutters, laminates, and flooring, as well as creating various souvenir products.

Besides the traditional CMYK four-color setup, the Power Pro 3200 supports six-color configurations (CMYK LC LM) with an added white channel for printing on colored and transparent materials, as well as UV varnish (V) for enhanced decorative effects.

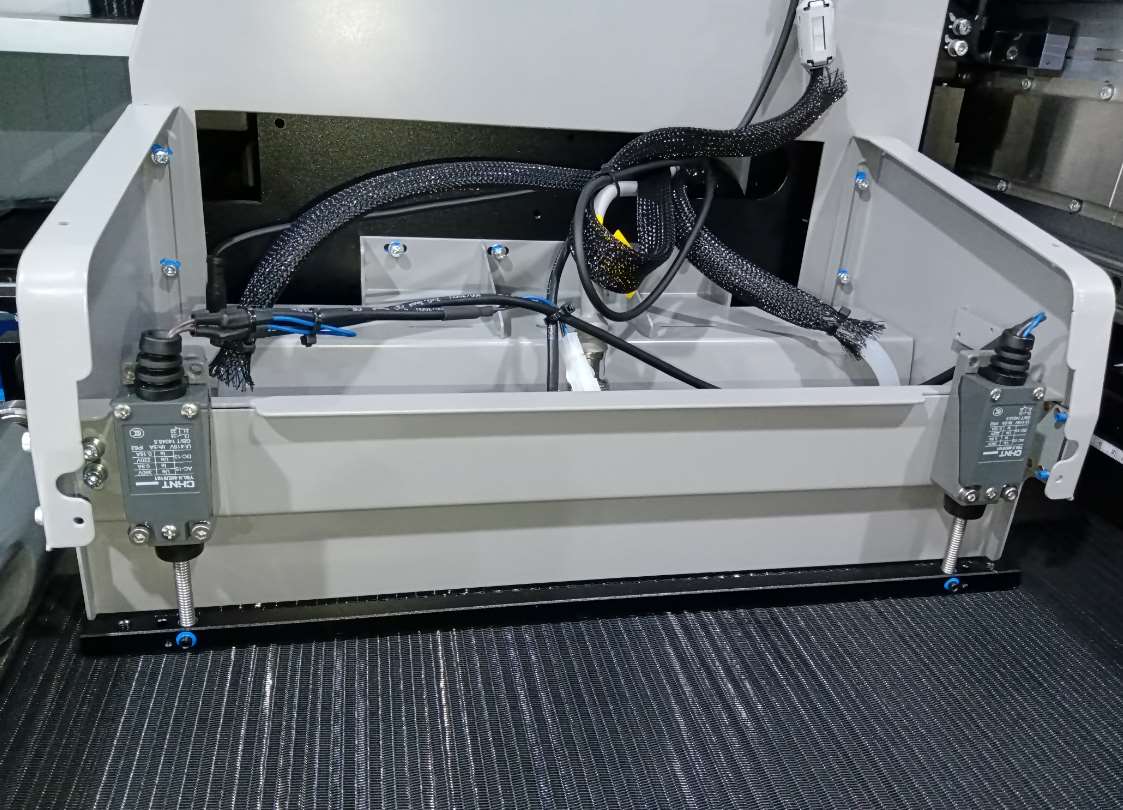

The Sprinter Power Pro 3200 is equipped with Igus E6 flexible cable carriers, ensuring long-term stable operation of all cables and hoses. The neatly arranged internal components allow for easy maintenance without entanglement.

Like other SPRINTER printers, the Power Pro 3200 uses components from renowned manufacturers: Fuji (Japan) and Leadshine (Shenzhen) servo motors, NSK (Japan) and PMI (Taiwan) bearings and ball screws, SMC (Japan) and AirTAC (Taiwan) pneumatic components.

(Contact us for more product details. National hotline: 4008-757-597)The Sprinter Power Pro 3200 offers a variety of printhead options:

- Ricoh GEN5 (Ink drop size 7–35 pl)

- Ricoh GEN6 (Min ink drop size 5 pl)

- Konica Minolta 6988H (Min ink drop size 13 pl)

- Konica Minolta 1024a (Ink drop size 6–24 pl)

The Sprinter Power Pro 3200 used in HUIDI’s showroom is equipped with the Konica 1024a printhead, offering high image quality and good printing speed for complex jobs.

Unlike traditional roll-to-roll printers, the Power Pro 3200 can raise the carriage height to 11 cm, making maintenance more accessible for operators.

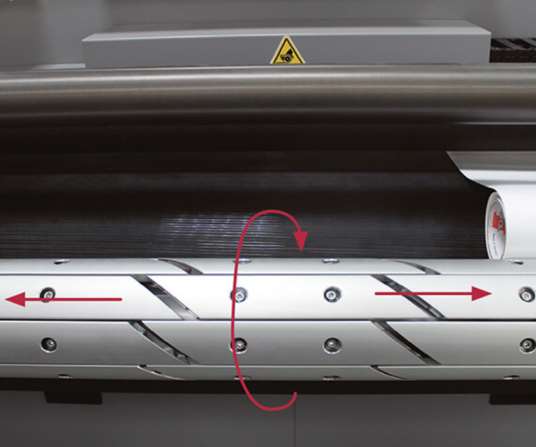

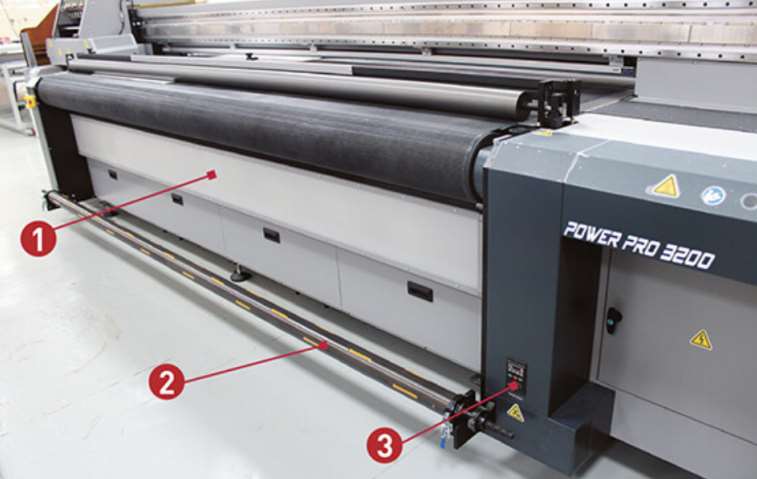

The speed of the rolls for unwinding (1) and winding of coiled materials depends on the torque of the motor. The operator can adjust the tension force of the coiled materials. The long roller (2) helps the vacuum to press rigid sheet materials that may not be perfectly flat to the work table. The sophisticated roller (3) for working with elastic materials (e.g. textiles) allows the web to be straightened when it is fed into the printing area, which ensures a stable production process. In the photo on the right, the arrows show the direction of rotation of the shaft and the movement of its individual parts, which stretch the material from the center to the sides as it moves into the print area

Double linear guides from the Japanese TNK (1) serve as a reliable support when moving a massive carriage. On the Smart-T printer presented in the showroom, instead of a timing belt, which is still used in most printers to move the carriage, an optional non-contact system is used - a linear drive operating on the principle of a "magnetic cushion". The advantages of a linear actuator are accuracy, speed and silence of work1. The optional high-precision magnetic encoder achieves a carriage accuracy of 0.001 mm. To neutralize this effect, the carriage is equipped with air ionizers on both sides. However, they may not be enough on particularly problematic materials. In this case, the operator can activate a powerful ionizer located along the entire printing area (3). For safety, this ionizer will automatically turn off when the printing process is complete. The registration bar (4) with stops (5) is used for fast positioning of sheet metal and workpieces. By helping to combat the skew of the printed material, they significantly increase the speed of the operator and, therefore, the productivity of the printer. The long roller (6), like the similar infeed roller, helps the vacuum to press rigid sheet materials to the work table. The vacuum on the mesh worktable (7) is created by two powerful pumps

A media illumination system is available on the front of the printer to help control print quality when working with roll-to-roll media (1). The bushings on the winding and unwinding shafts are attached using compressed air (photo on the right), which must be supplied to the printer from the side

The machine also features a universal anti-collision design, which protects the printheads from damage caused by collisions, extending their lifespan.

The Power Pro 3200 uses eco-friendly UV inks from well-known international brands, free of VOCs. The inks offer bright colors and excellent adhesion. For stretchy materials like leather, we offer neutral stretchable inks that perform well. This enables the Power Pro 3200 to print on a wide range of materials, including plastics (e.g., acrylic), standard and quartz glass, aluminum composite, wood, parquet, cardboard, banners, fabrics, natural and synthetic leathers, carpets, and cork coatings.

With an 8-color ink system, the Power Pro 3200 provides various color configurations, supporting CMYK, Lc, Lm, W, and V. It features a 1.5L large ink tank with an automatic stirring function to prevent ink sedimentation, ensuring printhead stability and preventing clogging. The machine also includes an automatic low-ink alert to remind operators to refill inks on time.

We tested ink consumption in different printing modes:

- 3-pass at 479×540 dpi: 4.6ml color ink consumption.

- 6-pass at 479×1080 dpi: similar consumption.

- 8-pass at 479×1440 dpi: 5.6ml color ink consumption.

In general, ink consumption differences are minimal; it’s recommended to prioritize speed as time is money.

The Sprinter Power Pro 3200 can also be equipped with front and rear platforms for handling board materials. The platforms automatically roll the materials in steps for convenient feeding and collection. When not in use, they fold up, saving space.

Summary:

Summary:

The Power Pro 3200 UV Belt Conveyor Printer is highly productive and suitable for various types of product manufacturing. As an outstanding representative of such equipment, it’s ideal for medium-to-large printing companies, advertising firms, and manufacturers—especially those entering the digital printing field, looking to expand production capacity and product range.