As the UV market continues to mature and develop, the user's imaging color requirements for UV printers are becoming more and more stringent, today SPRINTER editor take you to understand the UV printing to determine the printing color of several factors

Image processing and judgment

When selecting the image for UV printing, give preference to vector images in Ai or cdr format.

Image creation software can be used

Adobe illustrator,CorelDRAW,or Photoshop

File format of the image output EPS/TIFF/PDF/JPEG

After exporting the images, we need to determine the sharpness of the images.

Two steps to determine image clarity

After the image is exported, the image is enlarged to the print size, and the clarity of the image seen is the clarity of the actual sprayed image within 1 meter of the vision seen

Enlarge the image to 1:1 size, the clarity of the image seen

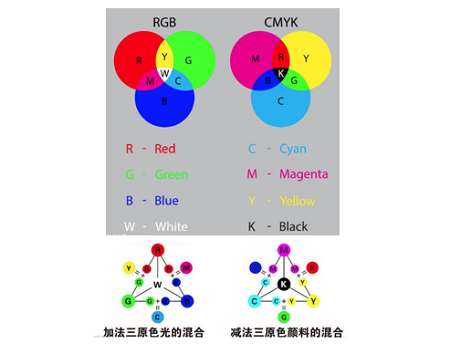

Color mode selection

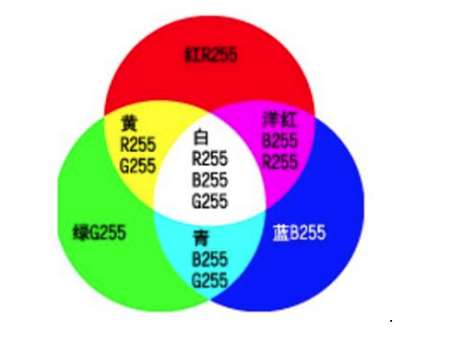

The color pattern is a way to record the color of an image. Theoretically, all the colors in nature can be obtained by

combining different intensities of the three color wavelengths:

There are two common color modes used in the UV printing industry: RGB and CMYKred, green and blue, which is often referred to as the three-color principle. It is also often referred to as the three primary colors or the three primary colors.

RGB Color Mode

RGB color mode, also known as true color mode, displays the highest quality images in RGB

Mode

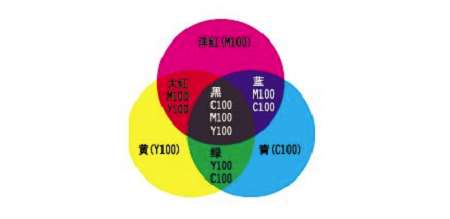

CMYK Color Mode

In CMYK mode, a percentage value can be assigned to each printing ink for each pixel

TIP:

Color images should be processed using Photoshop in RGB mode as much as possible, and then converted to CMYK mode before final output

The output mode of the picture is CMYK mode, if you use RGB color mode out of the picture, its computer display color and the actual airbrush out of the color is relatively far from the difference.

Ink selection

UV ink, waterproof, not easily decomposed by UV rays

Strong water resistance, light resistant, suitable for outdoor use

Suitable for printing metal, glass, ceramic, PC, PVC, ABS and other materials.

By adjusting the viscosity, hue, and brightness of the ink, a wide range of colors can be created.

By mixing two or more basic colors, you can obtain a variety of desired colors.

TIP:

It is particularly important that customers follow the manufacturer's specified ink in use

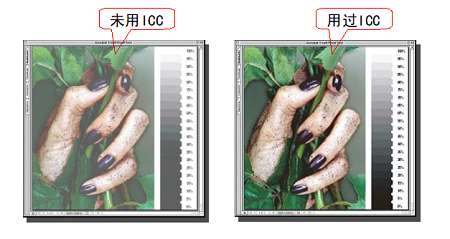

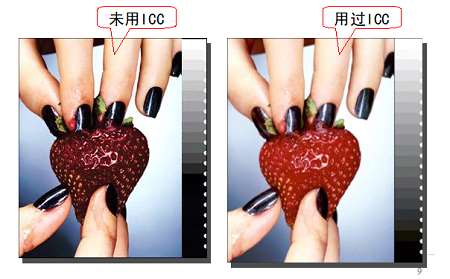

ICC Curve

UV printers are non-contact inkjet operation on the print media, rendering color patterns. The ICC curve is to specify the matching color value of each color to unify the color ratios with a specific inking scheme.

SPRINTER will develop a specific plan for the customer's processing situation before shipping the UV printer, from the characteristics of the machine, the processing process, processing materials, the use of ink in all aspects of the comprehensive, the machine's performance to the best.